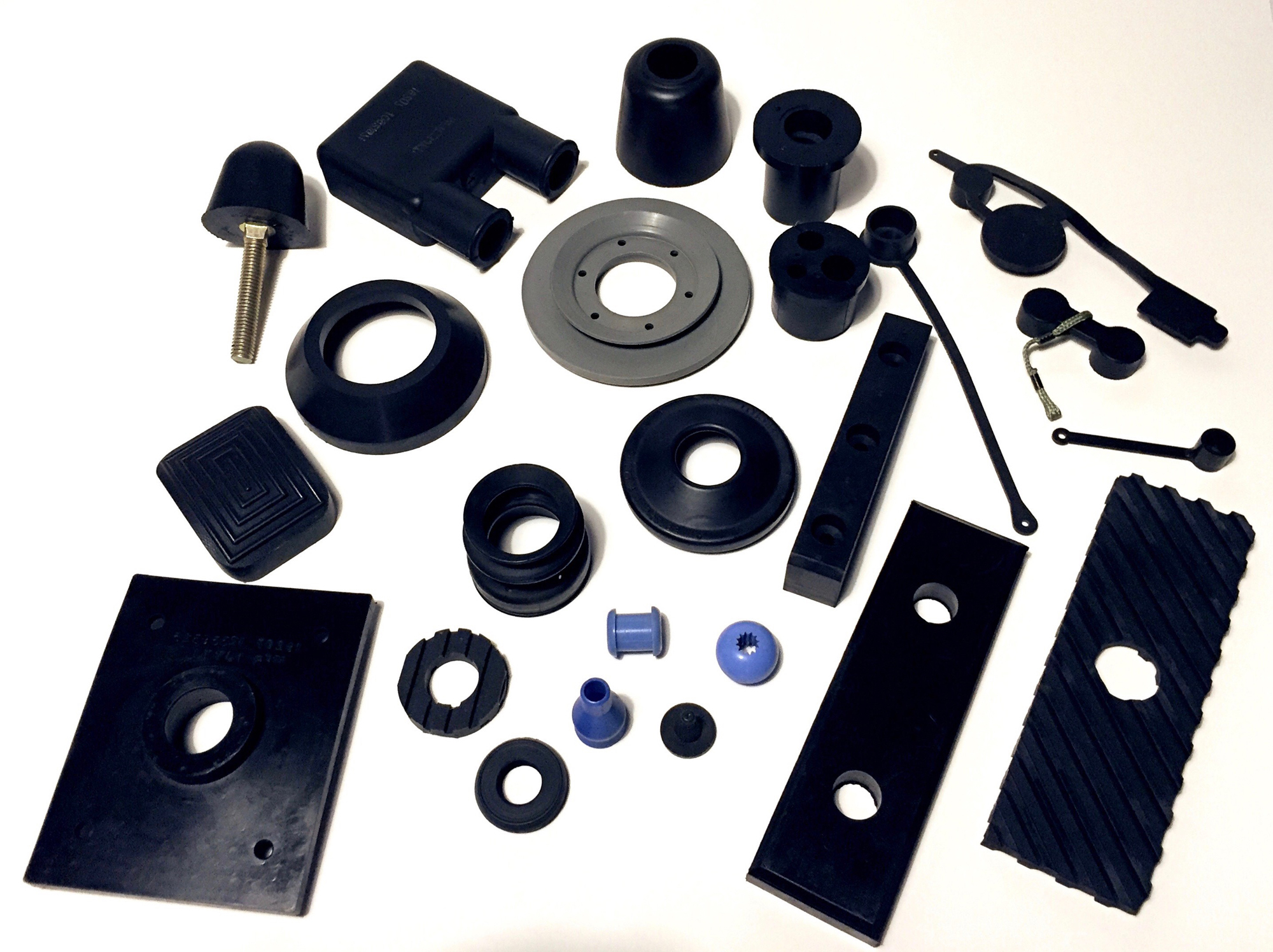

What We Have to Offer

For high-grade molded rubber, die-cut products, O-rings, and more, turn to Blade Industrial Products, Inc. in Wixom, MI. Our products and services are geared toward military and aerospace applications. However, we also extend our abilities to the transportation, plumbing, hardware, and appliance industries.

-

Rubber Injection Molding

The rubber injection molding process starts with uncured rubber that is fed into a rotating screw injection unit. When material is pulled into the injection unit it is heated to a preset temperature. The material is then injected into the mold cavity through a runner and gate system where it is held in the mold under heat and high pressure to cure the rubber compound (vulcanized). The cycle time is adjusted to reach the optimal level of cure. At the end of the cycle, mold is opened and the parts removed or ejected and the process repeats again.

-

Rubber Transfer Molding

Transfer molds contain a pot and a ram. Preformed material is loaded into the pot and the ram is used to force the material under pressure through the sprue holes in the bottom of the plate into the cavities. It is held under heat and pressure until the material is fully cures into the desired shape.

-

Rubber Compression Molding

Rubber compression molding is when raw materials are placed into the mold directly and hydraulic pressure is applied. Once the material is cured, the mold will be opened and the finished part will be removed.

O-Rings

O-rings are designed to keep fluids or gases from going in or out of a defined space. You can be sure that nothing will get past our O-rings. When you place an order for military spec O-rings, please use the NSN or the AS568 number, including the dash size and proper military prefix (such as AN, AS, MS, or NAS).

ASTM D2000 Material Designation (Type Class)

ASTM D2000 Suffix